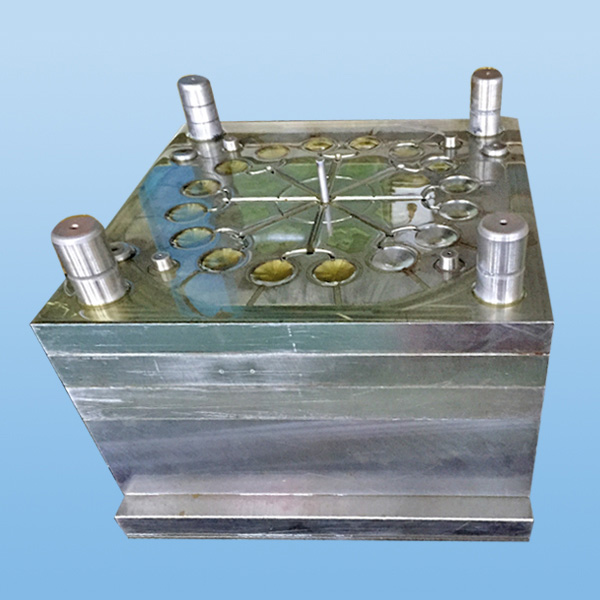

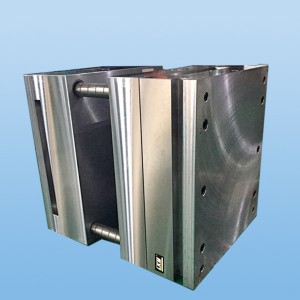

36mm mucegai VR Ochelari Lens

| Specificație | |

| numele produsului | 36mm mucegai VR Ochelari Lens |

| Numărul produsului | H207MJ |

| Tip | Mold Manufacturing |

| Utilizarea | Helmet Lens Mold, Ophthalmic Lens Mold, Sunglasses Glasses Mold, Myopic Lens Mold, Presbyopic Lens Mold, Industrial Eyeglasses Mold, HUD Lens Mold, Eye Protection Lens Mold, Optical Lens Mold, TV Lens Mold, VR Lens Mold, LED Optical Lens Mold, Fresnel Lens molds, Laser Lens molds, Ski lens Molds, Swimming Lens Molds, Precision Injection Molding Optical Lens Molds, Transparent Mask Molds, Goggle Molds, PC Lens Molds, PMMA Lens Molds, Hemispherical Lens Molds, Spherical Lens Molds, Aspherical Mirror Lens mold, Double Curved Lens Mold, Bent Lens Mold |

| Culoare | Mirror Finish |

| Logo design | personalizate |

| forma de proiectare | OEM / ODM |

| mărimea | OEM / ODM |

| Ambalare | Fumigare Cutii din lemn |

| materiale | Die otel: S136, S136H, NAK80, P20, 718H, etc. |

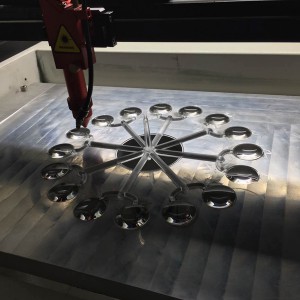

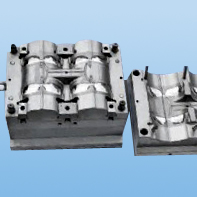

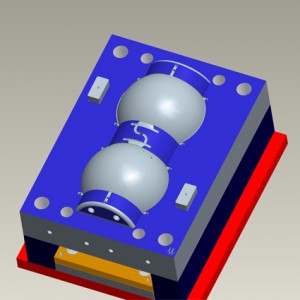

| Tehnologia de producție | Die Design, Die despărțire, CNC, Decupare sarma-electrod, masini-unelte, frezare, rectificare, scânteie electrică, lustruire, asamblare și Trial mucegai. |

| standard de testare | GB T 12554-1990, DME Standard, HASCO Standard |

Caracteristică Produs : With our complete molding process equipment, precision grinding and polishing equipment and mold design & technical team, Zhantuo Optics own mold room can rapidly develop various optical lens molds and lens peripheral fitting molds with the injection molding department and undertake various injection molds. Production. Mold parameters: Steel: using high-quality mirror steel, Lung Kee, ASSAB S136 \ S136H \ NAK80 \ 45 # quenched \ 60 # quenched \ P20H \ 718H \ 2316 for your choice; Molds: DME, HASCO, FUTABA, LKM; Cooling system: optimized design of circulating water, increase production efficiency, reduce your costs; Mid-term treatment: conditioning, increase hardness; Post-processing: vacuum heat treatment, azotizing; Die life: P20 normal use of not less than 300,000 beer times, S136 normal use up to 1 million beer times. Mold acceptance and delivery: ★ conformitate cu data de livrare convenită; ★ Mărimea mucegai determinată de client; ★ Client a confirmat planul de proces tehnic; ★ desene de proiectare mucegai și documente electronice; ★ conformitate cu cerințele clientului, depanare , până când atinge la asamblarea produsului calificat, poate fi produs în mod oficial; ★ Suprafața de testare a probei fara defecte cum ar fi deformarea, contracția sau gaura de injecție care afectează viziunea, și trece standardele de testare optice specificate de client.