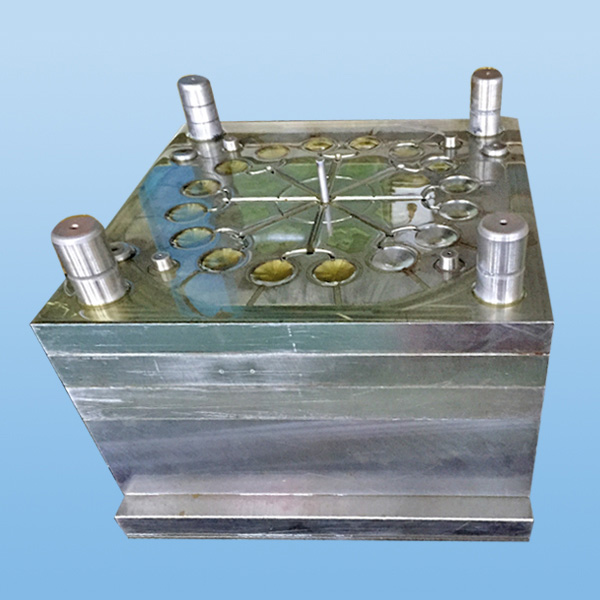

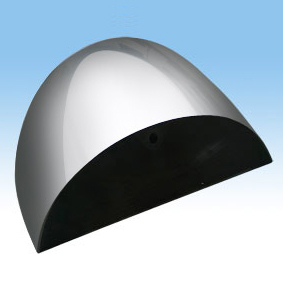

36mm acuan VR Kaca Lens

| spesifikasi | |

| Nama Produk | 36mm acuan VR Kaca Lens |

| Nombor produk | H207MJ |

| Jenis | Mold Manufacturing |

| menggunakan | Helmet Lens Mold, Ophthalmic Lens Mold, Sunglasses Glasses Mold, Myopic Lens Mold, Presbyopic Lens Mold, Industrial Eyeglasses Mold, HUD Lens Mold, Eye Protection Lens Mold, Optical Lens Mold, TV Lens Mold, VR Lens Mold, LED Optical Lens Mold, Fresnel Lens molds, Laser Lens molds, Ski lens Molds, Swimming Lens Molds, Precision Injection Molding Optical Lens Molds, Transparent Mask Molds, Goggle Molds, PC Lens Molds, PMMA Lens Molds, Hemispherical Lens Molds, Spherical Lens Molds, Aspherical Mirror Lens mold, Double Curved Lens Mold, Bent Lens Mold |

| Warna | Mirror Selesai |

| logo Design | disesuaikan |

| Design bentuk | OEM / ODM |

| saiz | OEM / ODM |

| pembungkusan | Pengasapan kotak kayu |

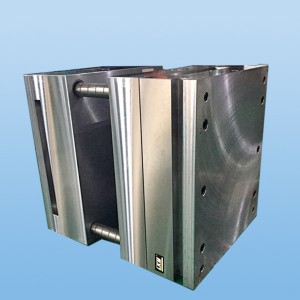

| bahan | Die keluli: S136, S136H, NAK80, P20, 718H, dan lain-lain |

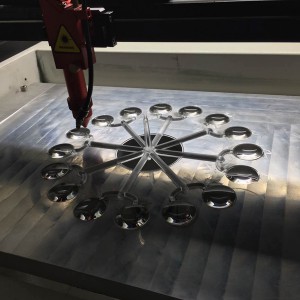

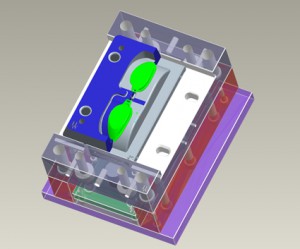

| Teknologi pengeluaran | Mati reka bentuk, mati perpisahan, CNC, memotong Wire-elektrod, Lathe, Milling, Grinding, bunga api Elektrik, Polishing, Dewan Perbicaraan dan acuan. |

| standard ujian | GB T 12554-1990, DME Standard, HASCO Standard |

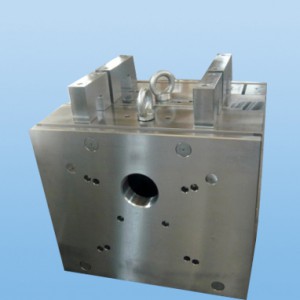

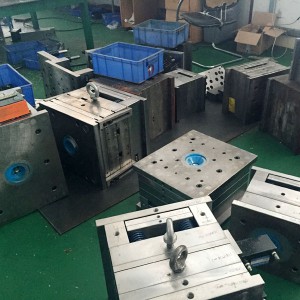

Ciri-ciri produk : With our complete molding process equipment, precision grinding and polishing equipment and mold design & technical team, Zhantuo Optics own mold room can rapidly develop various optical lens molds and lens peripheral fitting molds with the injection molding department and undertake various injection molds. Production. Mold parameters: Steel: using high-quality mirror steel, Lung Kee, ASSAB S136 \ S136H \ NAK80 \ 45 # quenched \ 60 # quenched \ P20H \ 718H \ 2316 for your choice; Molds: DME, HASCO, FUTABA, LKM; Cooling system: optimized design of circulating water, increase production efficiency, reduce your costs; Mid-term treatment: conditioning, increase hardness; Post-processing: vacuum heat treatment, azotizing; Die life: P20 normal use of not less than 300,000 beer times, S136 normal use up to 1 million beer times. Mold acceptance and delivery: ★ Menurut tarikh penghantaran yang dipersetujui; ★ Saiz acuan yang ditentukan oleh pelanggan; ★ Pelanggan mengesahkan pelan proses teknikal; ★ lukisan reka bentuk acuan dan dokumen elektronik; ★ Mengikut keperluan pelanggan, debugging sehingga mencapai kepada pemasangan produk layak, boleh secara rasmi dihasilkan; ★ permukaan sampel ujian tanpa sebarang kecacatan seperti ubah bentuk, pengecutan, atau lubang suntikan menjejaskan penglihatan itu, dan lulus ujian piawaian optik ditentukan oleh pelanggan.