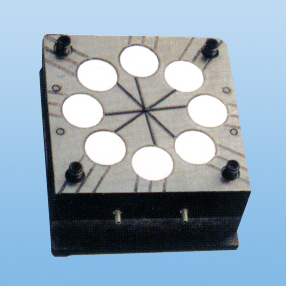

Mold Jarak bundher

| Keterangan | |

| Jeneng Product | Mold Jarak bundher |

| Panggil Product | H220MJ |

| Koleksi | Mold Manufacturing |

| nggunakake | Helmet Jarak Mold, Ophthalmic Jarak Mold, Sunglasses Kacamata Mold, rabun Jarak Mold, Presbyopic Jarak Mold, Industrial Eyeglasses Mold, HUD Jarak Mold, Protection Mripat Jarak Mold, Optical Jarak Mold, TV Jarak Mold, VR Jarak Mold, LED Jarak Optical Mold, cetakan Fresnel Jarak, cetakan Laser Lens, Ski lensa Molds, Swimming Jarak Molds, Precision Injection Molding Optical Jarak Molds, Molds Mask Transparent, Goggle Molds, PC Jarak Molds, PMMA Jarak Molds, hemisperikal Jarak Molds, Bulat Jarak Molds, Aspherical Mirror Jarak jamur , Double Sudhut mlengkung Jarak Mold, Bent Jarak Mold |

| warna | mirror Rampung |

| Desain Logo | selaras |

| Desain wangun | OEM / ODM |

| Size | OEM / ODM |

| packing | Fumigation Boxes Kayu |

| bahan | Die baja: S136, S136H, NAK80, P20, 718H, etc |

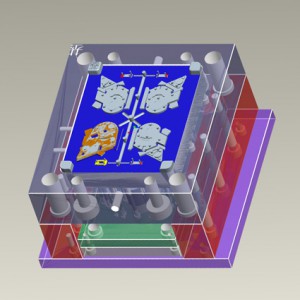

| Teknologi Produksi | Die desain, mati parting, CNC, Wire-elektroda nglereni, Bubut, Milling, Grinding, narik Electric, Polishing, Majelis lan Trial jamur. |

| standar testing | GB T 12554-1990, DME Standard, HASCO Standard |

Feature Product :

Karo peralatan proses ngecor lengkap kita, tliti mecah lan polishing peralatan lan jamur desain & tim technical, Zhantuo Optik duwe kamar jamur kanthi cepet bisa berkembang macem-macem cetakan lensa optik lan lensa cetakan fitting peripheral karo departemen ngecor injeksi lan nggarap macem-macem cetakan injeksi. Produksi.

paramèter Mold:

Steel: nggunakake pangilon baja kualitas, Lung Kee, Assab S136 \ S136H \ NAK80 \ 45 # sirep \ 60 # sirep \ P20H \ 718H \ 2316 kanggo pilihan;

Molds: DME, HASCO, FUTABA, LKM;

sistem cooling: desain optimized banyu sirkulasi, nambah efficiency produksi, nyuda biaya Panjenengan;

perawatan jangka Mid: kahanan, nambah atose;

Post-Processing: perawatan panas vakum, azotizing;

Die urip: P20 normal nggunakake saka ora kurang saka 300,000 kaping bir, S136 normal nggunakake nganti 1 yuta bir kaping.

acceptance Mold lan pangiriman:

★ Miturut tanggal pangiriman sarujuk;

★ The jamur ukuran ditemtokake dening customer;

★ Customer dikonfirmasi rencana proses teknis;

★ gambar desain Mold lan dokumen elektronik;

★ Miturut syarat customer, debugging nganti entuk kanggo patemon produk qualified, bisa diprodhuksi bakal resmi;

★ lumahing saka sampel testing tanpa cacat kayata ewah-ewahan bentuk, shrinkage, utawa bolongan injeksi nggowo pengaruh sesanti, lan pass standar test optik kasebut dening customer.