Kaus mom hlau Pwm

| specification | |

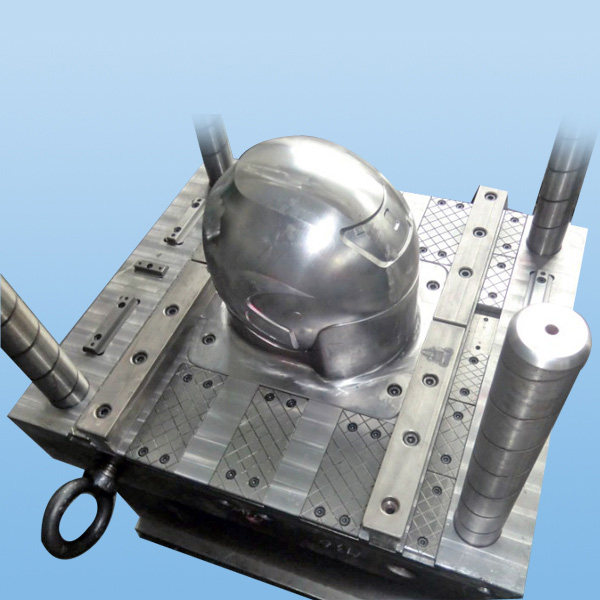

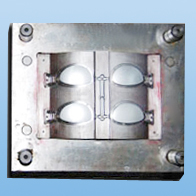

| khoom npe | Kaus mom hlau Pwm |

| khoom Number | H302MJ |

| hom | pwm Raug |

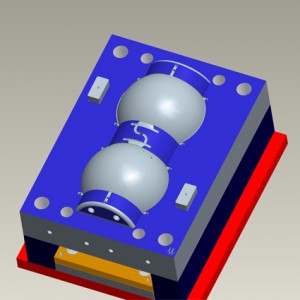

| siv | Nyob rau hauv tas li ntawd mus tso ua kho qhov muag lens pwm, Zhantuo Optical kuj lees paub ntau hom txhaj tshuaj pwm, yas pwm, hluavtaws cob pwm, yas txhaj pwm, txhaj tshuaj molding pwm, txhaj tshuaj molding pwm, precision yas pwm, thiab pwm qhib pwm rau yas tsev nyob tuaj pwm thiab molds. Ua, xws li txhua txhua hnub necessities pwm, qho khoom ua si pwm, hluav taws xob khoom plhaub pwm, tsom-iav accessories pwm, ntaus pob ncaws pob khoom plhaub pwm, kev kho mob ntaus ntawv plhaub pwm, pob tshab khoom molds. |

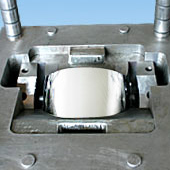

| Xim | Daim iav Finish |

| logo Design | Mekas |

| zoo tsim | OEM / ODM |

| loj | OEM / ODM |

| Cov | Fumigation Ntoo Thawv |

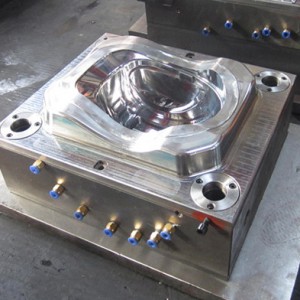

| ntaub ntawv | Tuag steel: S136, S136H, NAK80, P20, 718H, thiab lwm yam |

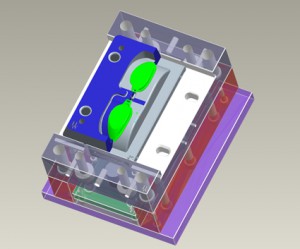

| Qhuav Technology | Tuag tsim, Tuag parting, CNC, Hlau-electrode txiav, Tshuab Dhos, Milling, Sib Tsoo, Electric txim, Polishing, los ua ke thiab mus sib hais pwm. |

| Xeem txheem | GB T 12554-1990, DME Standard, HASCO Standard |

Khoom Feature:

Nrog peb ua tiav molding kev cov khoom, precision sib tsoo thiab polishing khoom thiab pwm tsim & kev pab, Zhantuo Optics muaj pwm chav tsev muaj peev xwm sai tsim ntau yam kho qhov muag lens pwm thiab lens peripheral haum pwm nrog txhaj tshuaj molding department thiab lees paub ntau yam kev txhaj tshuaj molds. Qhuav.

Pwm tsis:

Steel: siv high-zoo daim iav steel, Lung Kee, ASSAB S136 \ S136H \ NAK80 \ 45 # quenched \ 60 # quenched \ P20H \ 718H \ 2316 rau koj xaiv;

Pwm: DME, HASCO, Futaba, LKM;

Cua txias system: qhov zoo tsim ntawm circulating dej haus, kom lawm efficiency, txo koj cov nqi;

Mid-lub sij hawm kho mob: txias, ua rau kom hardness;

Post-ua: lub tshuab nqus tsev tshav kub kev kho mob, azotizing;

Tuag lub neej: P20 qub ntawm tsis tsawg tshaj li 300,000 npias lub sij hawm, S136 qub mus txog 1 million npias lub sij hawm.

Pwm txais thiab tus me nyuam:

★ Raws li pom zoo tus me nyuam hnub;

★ Lub pwm loj txiav txim los ntawm tus neeg muas zaub;

★ neeg paub tseeb hais tias kev txheej txheem kev npaj;

★ Pwm tsim drawings thiab hluav taws xob cov ntaub ntawv;

★ Raws li cov neeg uas yuav tsum tau, debugging kom txog rau thaum ua tau rau cov khoom los ua ke tsim nyog, yuav thawm xyoo ua;

★ Deg ntawm kev soj ntsuam cov qauv tsis muaj tsis xws luag xws li deformation, shrinkage, los yog txhaj tshuaj qhov rau lub zeem muag, thiab dhau tus kho qhov muag kuaj cov qauv teev tseg los ntawm tus neeg muas zaub.